How to store your adhesive & primer canisters

Published: 24 January 2022

Updated: 11 February 2022

Here James Follows, Compliance Manager at Apollo Roofing, offers his canister storage advice and explains the regulations.

Roofing adhesive and primer canister products provide many benefits, including excellent coverage rates. Site trials have shown that the coverage of one canister can be the equivalent of up to six 6L tins of adhesive˟, reducing the number of containers needed to be stored. Canister products also give up to 8x faster and more professional application due to the pressurised system (compared to traditional products)˟, reducing project costs.

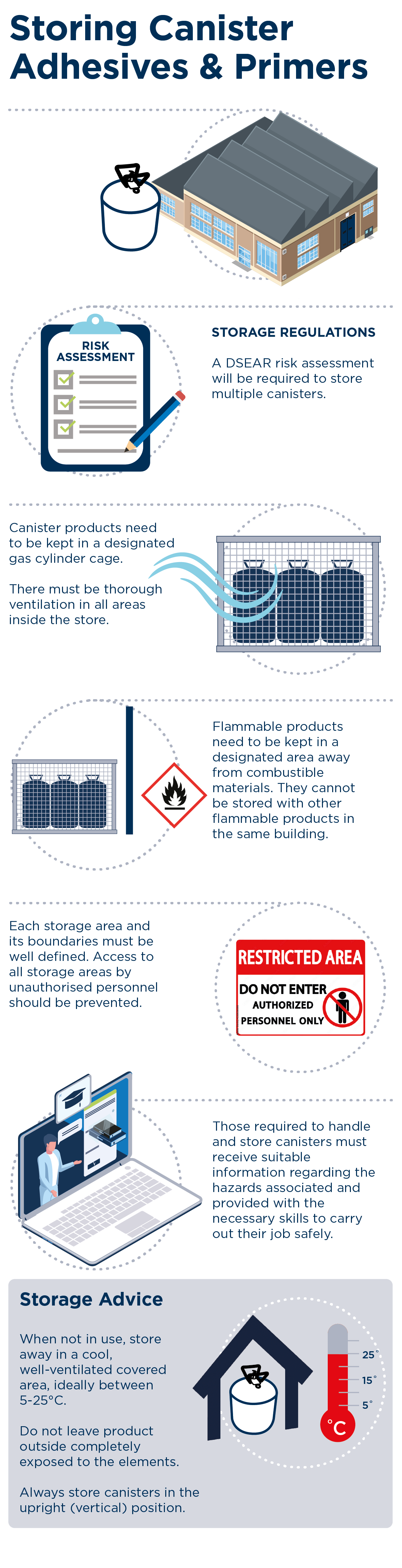

Storage Advice

When not in use, your roofing adhesive and primer canisters and the associated equipment should be safely stored away in a cool, well-ventilated covered area, ideally between 5-25°C. Always store canisters in the upright (vertical) position. Do not leave product outside completely exposed to the elements and keep your canisters off concrete floors, which can get very cold.

If your product has been stored at temperatures outside of this bracket, you should try to get the canister to an ambient temperature before starting work. This will ensure the product is ready to use and will guarantee the shelf-life, coverage rates and performance as stated on the technical data sheet.

Most adhesive and primer canisters will have a shelf life of 12 months, providing the canister has been maintained correctly. It is important to adhere to a ‘first in, first out’ (FIFO) stock rotation to ensure you are always using the product with the shortest remaining shelf life first.

Storage Regulations

There are storage regulations for storing multiple canister adhesives and primers, as there are with storing other products containing hazardous substances. A DSEAR risk assessment will be required if you are storing multiple canisters. Apollo Roofing’s Compliance department can advise.

The storage of substances is covered under the ‘HSG 71 Chemical Warehousing: The Storage of Packaged Dangerous Substances 2009’ regulations, with further specific guidance for canister products covered in the ‘Storage of Full and Empty LPG Cylinders and Cartridges Code of Practice 7 LP Gas Association 2004’.

Existing buildings can be permitted to hold 400 kilos of gas, equivalent to approx. 80 canisters, but your canister products will need to be kept in a designated gas cylinder cage. You must ensure that there is thorough ventilation in all areas inside the store.

Any flammable products will be required to be kept in a designated area away from any combustible materials. They cannot be stored with other flammable products in the same building, but a brick/concrete partition can be classed as a new building. The height of the partition should be at least 2 meters high and should be constructed to achieve at least 30 minutes fire-resistance.

The below chart shows the recommendations for the separation/segregation of different classes of substances:

There is also the option to have a container (with open or ventilated sides) in a yard as your canister storage.

Each storage area and its boundaries must be well defined. Access to all storage areas by unauthorised personnel should be prevented and such places should be marked with notices prohibiting smoking and the use of naked flames.

For further information around the storage requirements of the storage room, please refer to ‘Storage of Full and Empty LPG Cylinders and Cartridges Code of Practice 7 LP Gas Association 2004’ guidelines.

All of those required to handle and store canister products must receive suitable information and instruction regarding the hazards associated with the product being stored and provided with the necessary skills and knowledge to carry out their job safely.

Please contact Apollo’s Compliance department or speak with your Account Manager for further assistance. Alternatively, more information is available at https://www.hse.gov.uk/pubnS/priced/hsg71.pdf or through Liquid Gas UK.

˟InsuBond Solvent-Free Insulation Adhesive vs InsuBond Spray-Applied Insulation Adhesive

Our below infographic summarises the key points:

Sign up to our newsletter to get our blogs delivered straight to your inbox

This form is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.