Benefits of Roofing Canister Adhesives & Primers

Published: 18 May 2022

Updated: 18 May 2022

Darrell Tibbins, Director of Technical, explains Apollo Roofing's history as polyurethane canister innovators and the benefits of these spray-applied systems.

Canister systems provide reliability and give high performance, with speed, precision and economical coverage. Each pressurised canister allows contractors to prepare roofing areas and bond insulation, membrane and detail work quickly, simply and professionally.

Apollo Roofing – Polyurethane (PU) & Canister Innovators

Polyurethanes have a long reliable history. Products are known for their strength and durability, and are capable of withstanding extreme conditions and temperatures.

Apollo Roofing have been pioneering PU adhesive technology for over 50 years. They were the first UK manufacturer to put PU adhesives into the spray-applied pressurised canister system. The new systems revolutionised the market, allowing for improved application techniques and savings in cost and time, whilst still keeping the strength of a PU.

Wind uplift is a major concern within the industry, with roof failure having the potential to result in significant financial loss and damage to reputation. Apollo Roofing were also the first UK adhesive manufacturer to conduct independent dynamic wind uplift testing on their canister range (as part of a full system build). All canister products tested for wind uplift resistance significantly exceed requirements as part of a full system build⋆.

⋆Canister products tested for wind uplift: RoofPrime (A3994) Spray-Applied Primer, RoofPrime (A8679) Non-Flammable Spray-Applied Primer, InsuBond (A1399) Spray-Applied Insulation Adhesive, FleeceBond (A1270) Spray-Applied Fleece Membrane Adhesive, RoofBond (A1297) Spray-Applied Multipurpose Membrane Adhesive, MemBond (A3931) Spray-Applied EPDM Membrane Adhesive. Please contact us for more information or for the full reports.

Canister Benefits

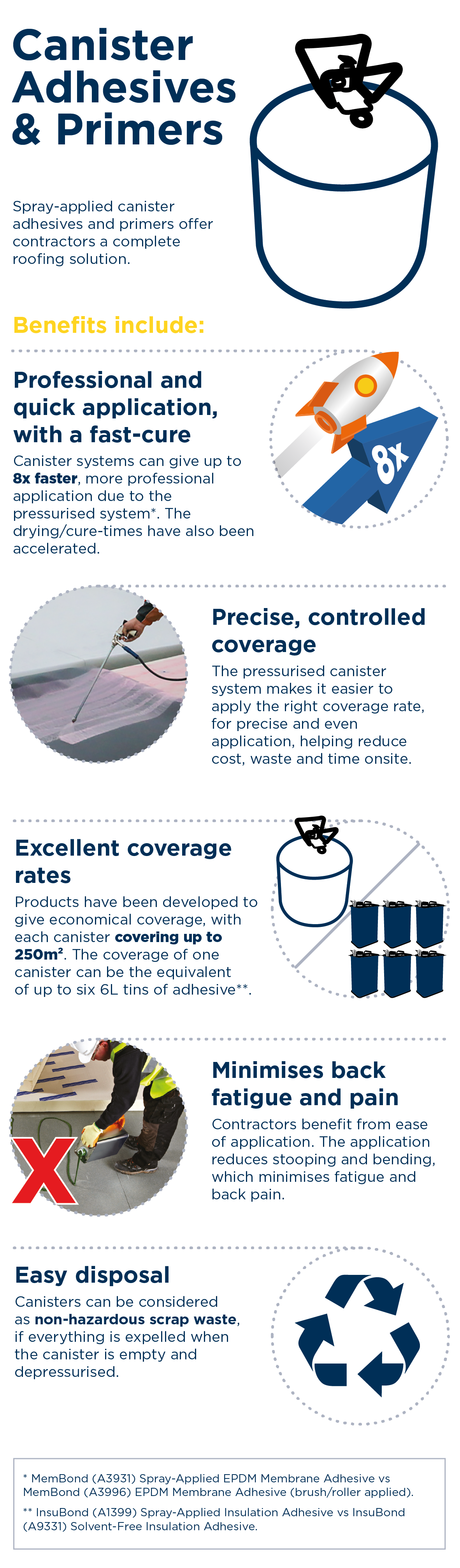

Spray-applied canister adhesives and primers offer contractors a complete roofing solution. Benefits include:

- Professional and quick application, with a fast-cure

- Precise, controlled coverage

- Excellent coverage rates

- Minimises back fatigue and pain

- Easy disposal

Professional and quick application, with a fast-cure

Canister systems can give up to 8x faster, more professional application due to the pressurised system (compared to traditional products)⋆. The drying/cure-times of all the canister products have also been accelerated. All of this helps to minimise time spent onsite.

⋆MemBond (A3931) Spray-Applied EPDM Membrane Adhesive vs MemBond (A3996) EPDM Membrane Adhesive (brush/roller applied). Please contact us for more information.

Precise, controlled coverage

It can be easy to apply too much adhesive with a tin-applied product, which increases cost. The pressurised canister system helps to reduce cost, waste and time onsite. It takes the guess work out of adhesive application and makes it easier to apply the right coverage rate, for precise and even application every time. The pressurised system also ensures all of the adhesive in the canister is expelled/used.

The adjustable spray-gun allows for controlled coverage, resulting in less mess and improving the aesthetics of the laid roof.

Excellent coverage rates

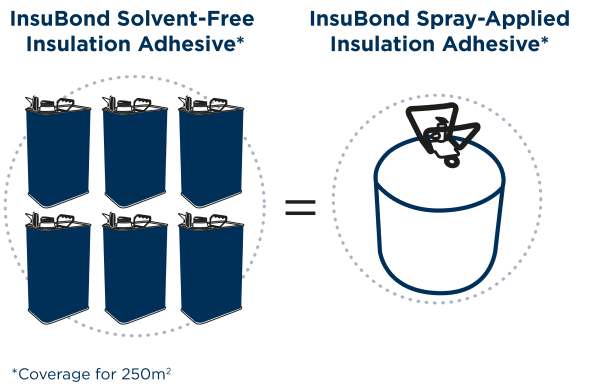

Products have been developed to give economical coverage, with each canister covering up to 250m². The same amount of adhesive in a tin would typically cover 100m². This gives an approximate cost-saving of 20% (compared to traditional products).

Using canister products can also reduce the number of containers needed to be transported and stored onsite, with the coverage of one canister being the equivalent of up to six 6L tins of adhesive⋆.

The coverage of the canister adhesives is also more consistent at cooler temperatures than traditional adhesives.

⋆InsuBond (A9331) Solvent-Free Insulation Adhesive vs InsuBond (A1399) Spray-Applied Insulation Adhesive.

Minimises back fatigue and pain

Contractors using the canister systems will benefit from ease of application. Unlike traditional bead-applied/roller-applied products, the application reduces stooping and bending during application, which minimises fatigue and back pain. This also helps to improve performance and reduce the risk of permanent back problems, which is a common problem reported amongst roofing contractors.

Easy Disposal

With the disposal of hazardous waste containers a key issue amongst contractors, unlike standard packaging, canisters can be considered as non-hazardous scrap waste (if everything is expelled when the canister is empty and depressurised).

After the simple instructions for emptying and depressurising have been followed, the canister will be empty of any hazardous materials and will also be depressurised. Therefore, it can be considered as scrap metal in accordance with the national or local waste company, under code EWC 15 01 04* (empty aerosol, no hazardous residues). Canisters are therefore easy to dispose of, and being a bigger unit, there is also less industrial waste compared to tin products.

Apollo Roofing provide a range of spray-applied canister products for all your requirements, including adhesives for insulation and a range of membranes (unbacked & fleece backed EPDM & PVC, and bituminous membranes), as well as primers (for SA membranes/VCLs). The systems have been designed to make applying adhesive and primers more comfortable, easier and faster. See more about each product below:

- RoofPrime Spray-Applied Primer

- RoofPrime Non-Flammable Spray-Applied Primer

- InsuBond Spray-Applied Insulation Adhesive

- FleeceBond Spray-Applied Fleece Membrane Adhesive

- MemBond Spray-Applied EPDM Membrane Adhesive

- MemBond Spray-Applied Bituminous Membrane Adhesive

- RoofBond Spray-Applied Multi-Purpose Membrane Adhesive

Contact us for more information.

The benefits of roofing canister adhesives and primers are summarised in the below infographic:

Sign up to our newsletter to get our blogs delivered straight to your inbox

This form is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.